PAPPARDELLE PILLARS

Investigating Column Fluting through Digital Fabircation and Clay

Material Systems instructed by Martin Bechtold

Harvard Graduate School of Design, 2018

in collaboration with Andy Bako (computation script management)

Throughout the past five decades, architectural construction has seen an exponential increase in the use of automated systems to employ methods of mass standardization. However, while serving as an effective method to reproduce standard components, until very recently, these technologies have been underutilized in the production of custom components. In contemporary design practice, the newfound pervasiveness of digital fabrication has enabled designers to perform experiments in customization and serial production. Buildings such as the Broad by Diller, Scofidio, and Renfro are not only examples of the possibility for customization, (managed by digital methods in design and fabrication), but also serve as examples of the ubiquity of such techniques due to their employment at a large scale. Moving forward, the emergence of mass customization provides agency to architectural ornamentation once again, an aspect of the discipline largely ignored and scrutinized due to the modern movement’s minimalist agenda.

fig. 00 Still life arangement of column samples on asphalt.

fig. 01 Research problem was in reference to pasta manufacturing which is based on a standard set of methods that can yield custom results.

fig. 02 The hypothesis was in reference to Hasbro’s Playdo which was a top down approach with nested bottom up processes to create ornament inherent to both ceramics as a material and digital fabrication as a method.

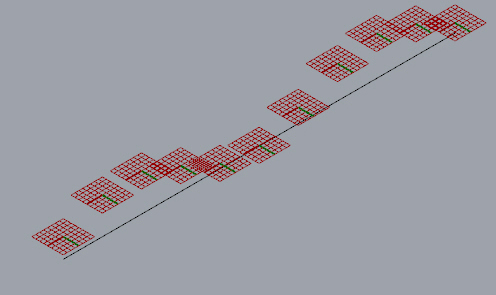

fig. 03 Custom nozzles create base extrusion shape and flow characteristics to track incremental toolpath complexity.

fig. 04 Robot arm was used to control precises z-axis displacement and rotation with standardized extruder fitted on tool tip; custom 3D printed nozzle attaches onto extruder.

fig. 05 Control Path

fig. 06 Translation

in Z-Axis

fig. 07 Rotation

in Z-Axis

fig. 08 Translation & Rotation

in Z-Axis

fig. 09 Rotation-dominant toolpath with “quattrofoglio” extrusion tip.

fig. 10 Test Sample 1

- Z-axis Δ 24 mm per circumference

- Z-axis Δ 4mm in per 100 mm arc length

- XY-plane Δ 5° per 100 mm

fig. 11 Test Sample 2

- Z-axis Δ 20 mm per circumference

- Z-axis Δ 6mm in per 100 mm arc length

- XY-plane Δ 25° per 100 mm

fig. 12 Test Sample 3

- Z-axis Δ 15 mm per circumference

- Z-axis Δ 7mm in per 100 mm arc length

- XY-plane Δ 35° per 100 mm

fig. 13 Test Sample 4

- Z-axis Δ 15 mm per circumference

- Z-axis Δ 7mm in per 100 mm arc length

- XY-plane Δ 45° per 100 mm

fig. 14 Test Sample 5

- Z-axis Δ 15 mm per circumference

- Z-axis Δ 10mm in per 100 mm arc length

- XY-plane Δ 55° per 100 mm

fig. 15 Close-up detail shot of fluting.